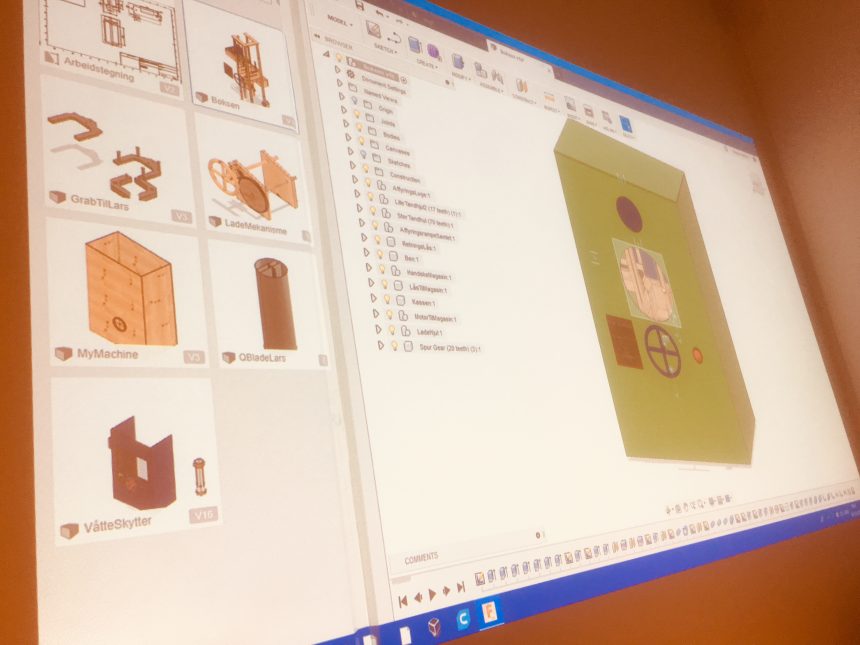

Great example of MyMachine Norway on how STEP 3 looks like. Technical secondary school students at Treteknikk in Tangen discuss the production options for this dream machine.

They concluded that it is difficult to build an entire machine in wood. In particular, the launch mechanism has proven to be difficult to construct in wood within the time they have available. After some testing, the ‘pop-up system’ has been replaced with a compressor, which and it also makes the machine safer so no children (or adults) get their fingers clamped in the machine.

So yes, it happens many times that the technical secondary school students and teachers improve or adapt the designs (made in STEP 2 by the university students) for them to be able to be produced.

This is just like in their future jobs, where on the one hand engineers need to take into account the production facility and on the other hand production specialist themselves are a as well a creative part of the whole process of bringing an idea to life. Bringing an idea to life in a professional context is always about respecting each other’s talents and collaborating.

We can’t wait to discover more about this dream machine becoming reality!